The environmental operating conditions of data centers worldwide have long been guided by recommendations made by The American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE).

The environmental operating conditions of data centers worldwide have long been guided by recommendations made by The American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE).

As the data center industry's knowledge and understanding of operating conditions has developed, ASHRAE has expanded its allowable temperature ranges and encouraged using techniques to reduce the energy consumed by cooling units run, or the time that the cooling units run, by making use of the outside temperature of air or water to cool the data center. Known as free cooling, this can make real energy savings and is now virtually mandated by the requirements of ASHRAE 90.1 - 20105.

Three Considerations to Unlocking Efficiencies

Cooling optimization technologies are key to achieving greater efficiency. However, understanding the different cooling choices and making the right cooling design decisions for a facility depends on a variety of factors beyond budget, such as power density and room size.

Airflow Containment

The physical separation of hot and cold air within the server room is the first stage to maximizing cooling system efficiency. Segregating hot and cold air can improve chiller efficiencies, reduce the total plant cooling capacity and create more free cooling hours. There are various methods and choosing one for your data center will depend on business need. Regardless, it is essential that whichever method is used, that the solution provides a strong seal to minimize leakage and ensure the pressure difference between the open and enclosed space is minimal.

Cabinet Infrastructure

Specifying cabinets that provide a complete front/rear seal around equipment and removing constraints around critical airflow design allows higher power and heat densities. Best possible isolation can be achieved with a combination of accessories including blank filler panels, equipment mounting area perimeter sealing air dams and floor tile cut out brush seal grommets, along with a system to remove the return air from the room into a suspended ceiling return air space.

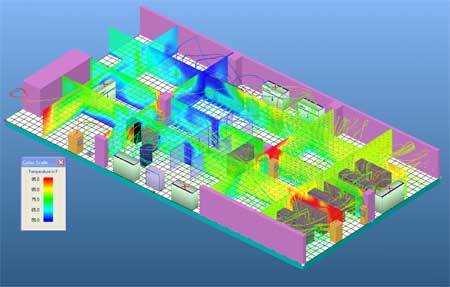

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) modelling or airflow modelling offers a more scientific and comprehensive design approach for simulating the cooling performance of data centers than was ever previously possible. Performing this type of simulation is much faster and more economical than building an actual layout but the results can provide the flow rate distribution through perforated tiles and rack inlet temperatures, as well as the underlying velocity, pressure and temperature fields.

Read the full article to learn more about how you can increase your data center efficiency and uptime, and contact a Chatsworth Products (CPI) representative to schedule on on-site visit.

Brittany Mangan, Digital Content Specialist