The Challenge

The Challenge

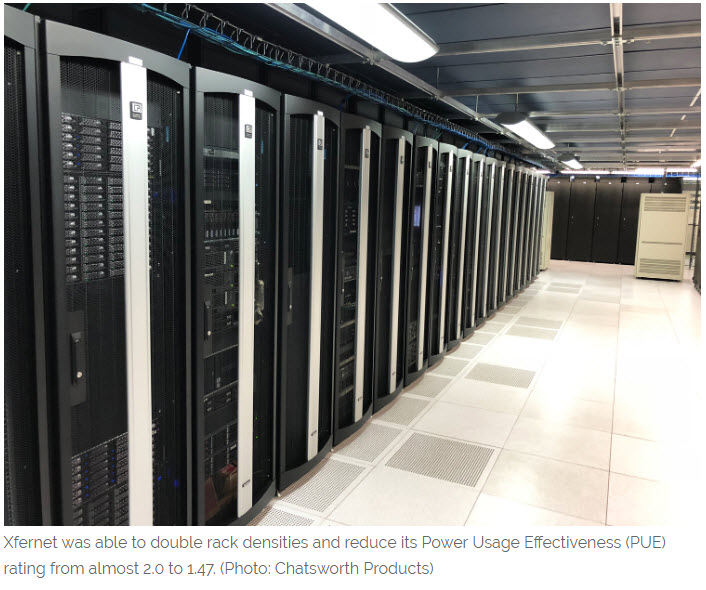

After significant growth, Xfernet, a Los Angeles-based colocation, needed to migrate its facility into a 14,000 square foot data center space with shallow raised floors, low ceilings and a limited footprint for new cooling equipment.

At its current 200 watts per square foot, the company needed to reduce the physical white space of the data center to achieve higher rack densities. The white space was then constrained to 10,000 square feet to enable double the rack density at 4-5 kW per cabinet (20 square feet per rack).

At those densities, adding more air conditioning to the room would not be a cost-effective option, particularly in the long term, according to Sam Scott, Xfernet's CEO and project lead.

The Solution

Scott needed to find a solution that would provide ideal airflow to cool each rack, even though the room had low drop ceiling and shallow raised floors, which limited the amount of airflow volume into the room.

In searching for a solution, Scott learned about CPI's Passive Cooling® technology. Passive Cooling completely segregates hot and cold air, and can be applied at the cabinet or aisle level, providing increased equipment cooling performance in all elements of the data center mechanical plant, thereby reducing overall energy costs.

In Xfernet's case, cabinet-level Passive Cooling was the ideal solution: by deploying cabinets with Vertical Exhaust Duct, airflow can be effectively managed, regardless of architectural constraints.

The Results

Xfernet was able to double rack densities and reduce its power usage effectiveness (PUE) rating from almost 2.0 to 1.47, mainly because of the efficiencies from CPI Passive Cooling.

"We saw the improvement immediately once we implemented the cabinets. It allowed us to fully service our clients." Scott explained.

If you're interested in learning more about how CPI helped Xfernet, or need to justify implementation of a new cooling approach, review and share the complete case study.

Brittany Mangan, Digital Content Specialist