In the age of the Internet of Things (IoT), the increasing need for reliable networks has driven smaller data centers to consolidate or in some cases, move to colocation providers where a single server rack may support numerous pieces of equipment.

In the age of the Internet of Things (IoT), the increasing need for reliable networks has driven smaller data centers to consolidate or in some cases, move to colocation providers where a single server rack may support numerous pieces of equipment.

As a result, power loads continue to increase. A few years ago, for example, an average cabinet within a medium to large data center could deliver 3-4 kW of power. Today, the same cabinet is capable of delivering between 8-15 kW.

Maintaining high power loads at optimum equipment temperatures, all while keeping energy consumption down, is challenging but possible. In fact, according to a 2014 report by the Natural Resources Defense Council (NRDC), if only half of the savings potential for data center efficiency were realized, energy consumption in U.S. data centers could be cut by as much as 40 percent. This means there’s still a lot of room for improvement.

Through efficient airflow management, it is possible to effectively and economically maintain electronic equipment operating at optimum temperatures.

Chatsworth Products (CPI) has proven this with its Passive Cooling Solutions, which provide equipment cooling performance in all elements of the data center, thereby reducing overall energy costs.

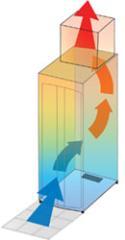

The Vertical Exhaust Duct placed at the top of each cabinet allows for the hot exhaust air from the back of equipment to rise. As it rises, it increases speed, forming a low-pressure area along the back of the cabinet, which pulls hot exhaust air from other servers into the stream.

Air flows through the Vertical Exhaust Duct to the ceiling plenum, drawing the hot air out of the cabinet and allowing for cool air to come in. Benefits of CPI Passive Cooling include:

- Supports extreme heat loads—30 kW and above

- Delivers uniformly cold intake air temperatures to all equipment

- Allows increased room temperature and higher set-points on cooling equipment and chilled water temperatures, for more free cooling hours using low-cost economizers.

- Increases CRAC cooling capacity two to three times, allowing use for higher equipment densities and energy cost savings.

As the IoT stimulates increase in equipment power densities at the rack level, the entire infrastructure within the data center must be reassessed. To get more insight into what organizations need to consider to achieve thermal efficiencies in their data centers, be sure to view a recent presentation given by Luca Rozzoni, CPI Sr. Product Manager for Europe, at the 2016 BICSI UK & Ireland.

With CPI Passive Cooling Solutions, you can maximize your cooling efficiencies without the need for additional CRAC units, in-row air conditioners or liquid cooling solutions. For detailed information on CPI Passive Cooling and energy efficiency, visit our website.

Raissa Carey, eContent Specialist