For the first time since the early 2000s, a new colocation facility is planned for San Francisco, California, U.S. According to fifteenfortyseven, it is unlikely another will be planned over the next decade, given the space and power constraints. There is a host of other adversities, as well.

For the first time since the early 2000s, a new colocation facility is planned for San Francisco, California, U.S. According to fifteenfortyseven, it is unlikely another will be planned over the next decade, given the space and power constraints. There is a host of other adversities, as well.

When it comes to building in a seismically active city like San Fransciso, there are unique architectural and engineering challenges. And, with California’s Net Zero energy goals by 2030, the stakes are even higher. Seismic areas require specific building codes and installation guidelines to ensure the safety of people, and the protection of expensive equipment. San Francisco has one of the most expensive commercial real estate square footage in the country. All of this adds up to a costly and challenging endeavor.

Raissa Carey, Chatsworth Products’ (CPI) Technical Writer and Public Relations Specialist, lists key considerations regarding the selection of infrastructure elements, the management of space, building code compliance, and reducing costs.

Specifying an Infrastructure for 10 Years Down the Road

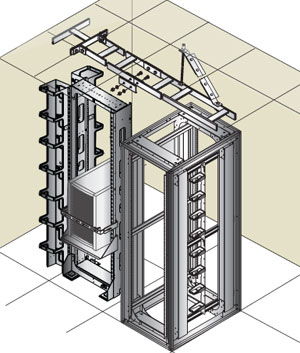

Any rack can be used in a seismic area, but seismic racks designed for seismic applications provide higher load ratings and can be filled with equipment, whereas with nonseismic racks, multiple racks are needed.

Most manufacturers only publish the static equipment load of their racks and cabinets in product specifications. Static loads range between 1,500 pounds to 3,500 pounds per rack, but it is important to remember that the static equipment load only provides the value for how much the rack can safely hold when still. It does not consider the effect of vibration on the rack. Seismic equipment load is calculated based on code requirements.

Reputable manufacturers test load racks specifically designed for seismic applications that have heavily braced frames to resist side-to-side, front-back and up-down motion. The rack must survive the test with no structural damage. Several standard shaker tests are available, but traditionally, rack manufacturers use the Telcordia Technologies GR-63-CORE, Section 4.4 test for rack and rack-mount equipment, as the following video shows.

The article goes on to discuss other key considerations:

- Complying with energy efficiency code: The California Building code specifically requires data centers to include some form of aisle containment as a way to save energy, so it’s important to consider seismic enclosures that enable proper airflow containment practices.

- Mission critical data centers: Depending on the type of product, an OSHPD Special Seismic Certification Preapproval of Manufacturer’s Certification (OPM) may be required. If you are in the market for a seismic rack for a health care facility or tenant, use OSHPD’s OPM to short list a few of your favorite racks. Then, compare the details to find the highest seismic load. For permitting approvals outside of California, a local engineer makes the recommendation.

To read the entire article, “Mission Critical Earthquake Preparedness,” click here. To learn more about CPI’s seismic protection systems, click here.

Brittany Mangan, Digital Content Specialist