Chatsworth Products' (CPI) RMR® Industrial Enclosures provide primary protection of sensitive IT equipment in environments that are dusty, dirty, possibly wet, and that experience wide temperature variations. They are able to provide this type of protection because they are completely sealed when closed, and are IP- or NEMA-rated.

Chatsworth Products' (CPI) RMR® Industrial Enclosures provide primary protection of sensitive IT equipment in environments that are dusty, dirty, possibly wet, and that experience wide temperature variations. They are able to provide this type of protection because they are completely sealed when closed, and are IP- or NEMA-rated.

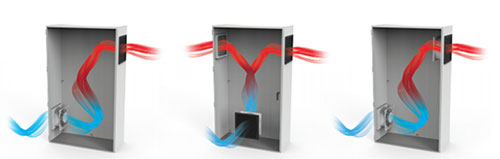

The sealed design of industrial enclosures does not allow for ventilation needed to cool internal electronics, so a filter fan or cooling unit is typically required to exhaust or eject heat from the enclosure. Like the enclosures, the filter fan or cooling unit need to be IP- or NEMA-rated to match (or exceed) the enclosure rating.

Filter fans with matching exhausts are a good choice where the amount of dust is minimal and when equipment within the enclosure can operate at higher temperatures than the temperature of the ambient air.

Use cooling units, enclosure-mounted air conditioners, to keep the enclosure completely sealed in areas with a lot of dust or where internal temperature must be tightly controlled.

Proper selection of filter fans and cooling units for industrial enclosures is critical to ensuring high equipment performance and availability, and improved energy efficiency.

Filter Fan and Cooling Unit Selection

When making a selection, consider these factors:

- Size of the enclosure

- Desired temperature within the enclosure

- Material type and insulation of the enclosure

- Supply voltage for the fan or cooling unit

- Type of enclosure

- Location of enclosure

- Whether the enclosure is bayed or stand-alone

- Ambient air temperature

- Anticipated heat load

Because of the complexity of the calculation, CPI suggests using online sizing tools to help select a correctly sized model. As an example, we suggest exploring Pfannenburg's Sizing Software (PSS).

To learn more about filter fans and cooling units for RMR® Industrial Enclosures, download a complimentary white paper.

Brittany Mangan, Digital Content Specialist